R9-302 for aerospace industry

Flame retardant epoxy prepreg

Aerospace industry requires specific features to apply structural composites both for interiors and exteriors. For this reason, epoxy prepreg have become one of the major items used in this market.

For more than 30 years, for instance, Airbus has pioneered the use of such materials in its commercial jetliners, from the cornerstone A310’s vertical stabiliser to today’s A350 XWB – on which more than half of the aircraft’s structure is composite.

Nowadays this trend is also valid for new transport generations such as small aircrafts, helicopters, drones and air taxis.

Do you know the key features of composite materials?

- Good mechanical properties

- Self-extinguish features

- Lower weight than other materials

- They allow to reach high standards of production efficiency.

Thanks to their features, composite materials can successfully applied to aircraft interiors such as:

- Cabin linings

- Seat structures

- Flooring

- Galleys

- Airshafts

While initially more expensive to produce than traditional parts, CFRP components allow aircraft operators to save money on future maintenance and time costs, as well as on fuel consumption.

Why to prefer CFRP to metal components?

An A350 XWB, for example, requires 50% fewer structure maintenance tasks, and the threshold for airframe checks is at 12 years (compared to 8 for the A380).

We are glad to present R9-302, an epoxy resin that has been specifically developed by Microtex Composites for the aerospace market, as well as rail and industrial ones.

Why R9-302 is so wow

- Flame retardant features

- Halogen free

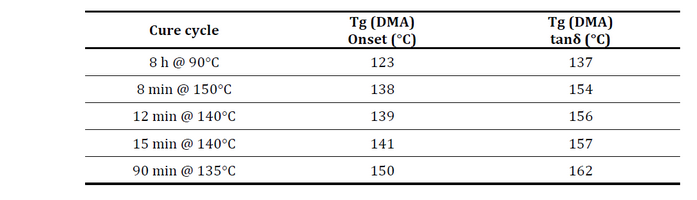

- High TG

- Low volatile content

- Suitable for autoclave and press cure

Prepreg technical features

R9-302 has an outlife of 3 weeks at 21°C and a storage life of 12 months at -18°C.

It is also available in a wide range of reinforced fibres such as carbon, aramidic, glass and special fabrics.

Certifications

R9-302 has been certified:

- FAR 25.853

Provides guidance material for demonstrating compliance with the Federal Aviation Regulations (FAR) pertaining to flammability of aircraft seat cushions. - EN 455-45: 2015

Specifies the reaction to fire performance requirements for materials and products used on railway vehicles.

Alternative curing cycles and tg’s

Read R9-302 technical sheet by clicking here

Take a look at all our matrices here