Composite materials for the marine market

The new thermosetting epoxy matrix X2-121

Masts, hulls and booms: composite materials are successfully used in the marine market thanks to their top features:

- lightness which allows to obtain performing boats

- resistance to different environmental conditions.

History of composite materials in the marine market

In marine market, different materials are used for the construction of boats. Although fiberglass is still one of the most common materials for budget boats, during the years different kind of resins have entered this market such as polyesters-isophthalic and vinylester matrices.

Nowadays, epoxy resins represent the optimal answer to the increasing needs of racing crafts and high budget yachts. Epoxy resins have better mechanical features than other types of resins and, when combined with carbon fiber, allow to get a superior final product both from performance and aesthetic point of view.

Did you know?

Thomas Edison was the first in 1879 to use in his experiments carbon fiber as incandescent filament for the first light bulb. Nevertheless, this material was improved a century after from Roger Bacon in 1958 and sold just two years after.

X2-121

The R&D dept. of Microtex Composites has developed X2-121: a thermosetting epoxy matrix with excellent cosmetic applications. This versatile, high-strength prepreg system is designed for “OoA” processing.

X2-121 is suitable to marine as well as industrial and sporty markets.

Why X2-121 is so wow

- Low curing temperature 80°C

- Medium tack

- Good drapeability

- Good surface finishing

- Low volatile content

Prepreg technical features

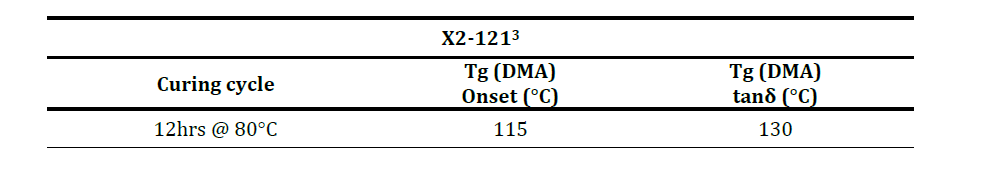

Curing temperature and tg’s

Read X2-121 technical sheet by clicking here