C-Block

Microtex Composites offers an interesting alternative solution for prototype / low series moulds and stock blocks to offer a new approach to manage the increasingly restrictive lead times imposed from the market.Download technical Sheet

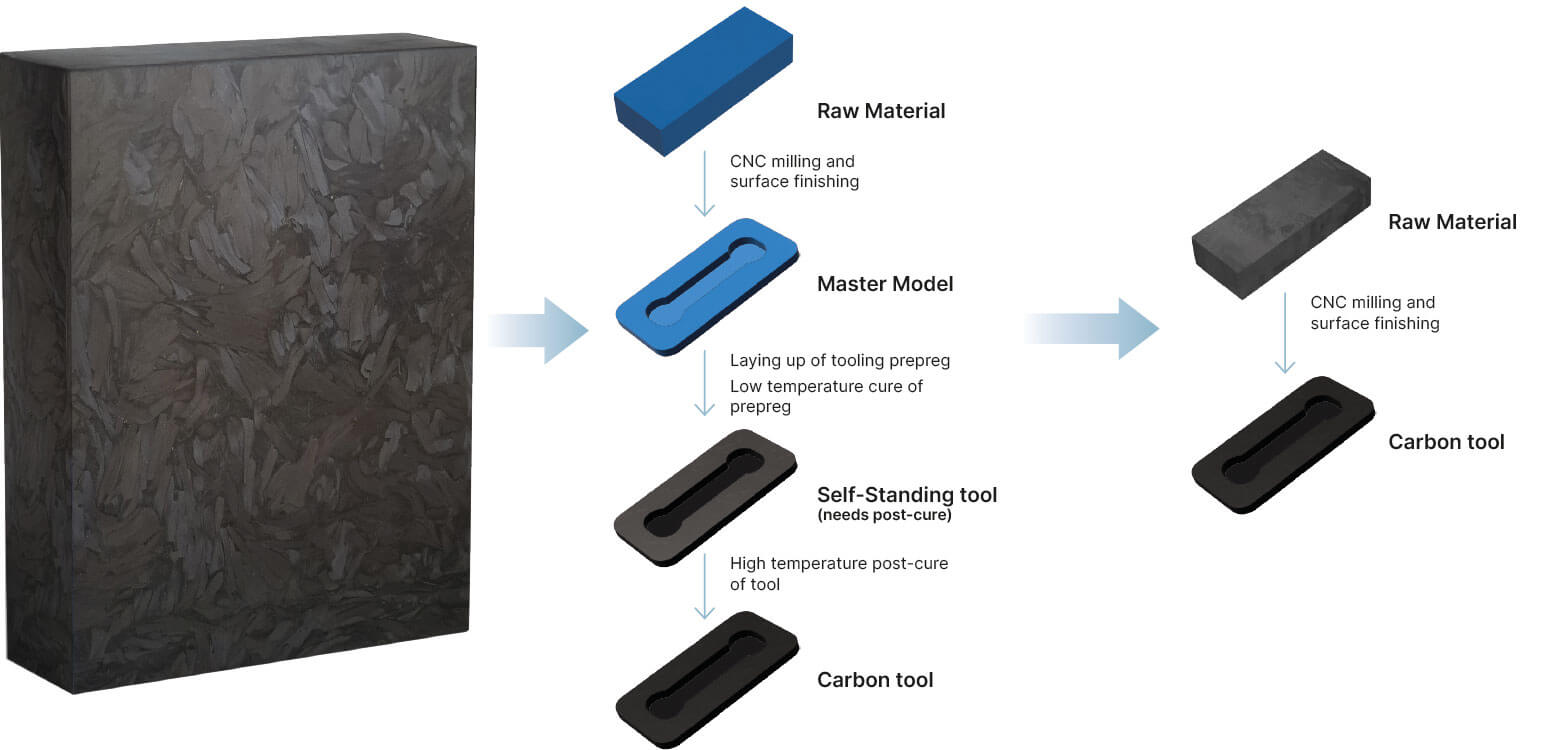

C-Block is a carbon fiber reinforced board obtained with a high pressure process (> 500 ton.) that generates a consistent and strong substrate with high edge solidity and high fiber volume fraction (55%). The board is supplied as «Ready to CNC» with a relevant service temperature of 160°c allowing users to mill mould or inserts directly from the raw block offering a linking solution between the benefit of cnc milling and a low cte typical of carbon fiber.

C-Block allows to implement typical approaches offered for epoxy resin tooling board without its limit of brittleness or short tool life, this means to guarantee an easy modifiable, repairable and extendable support that opens to various applications like direct mould, stock blocks milling and inserts for carbon fiber moulds.

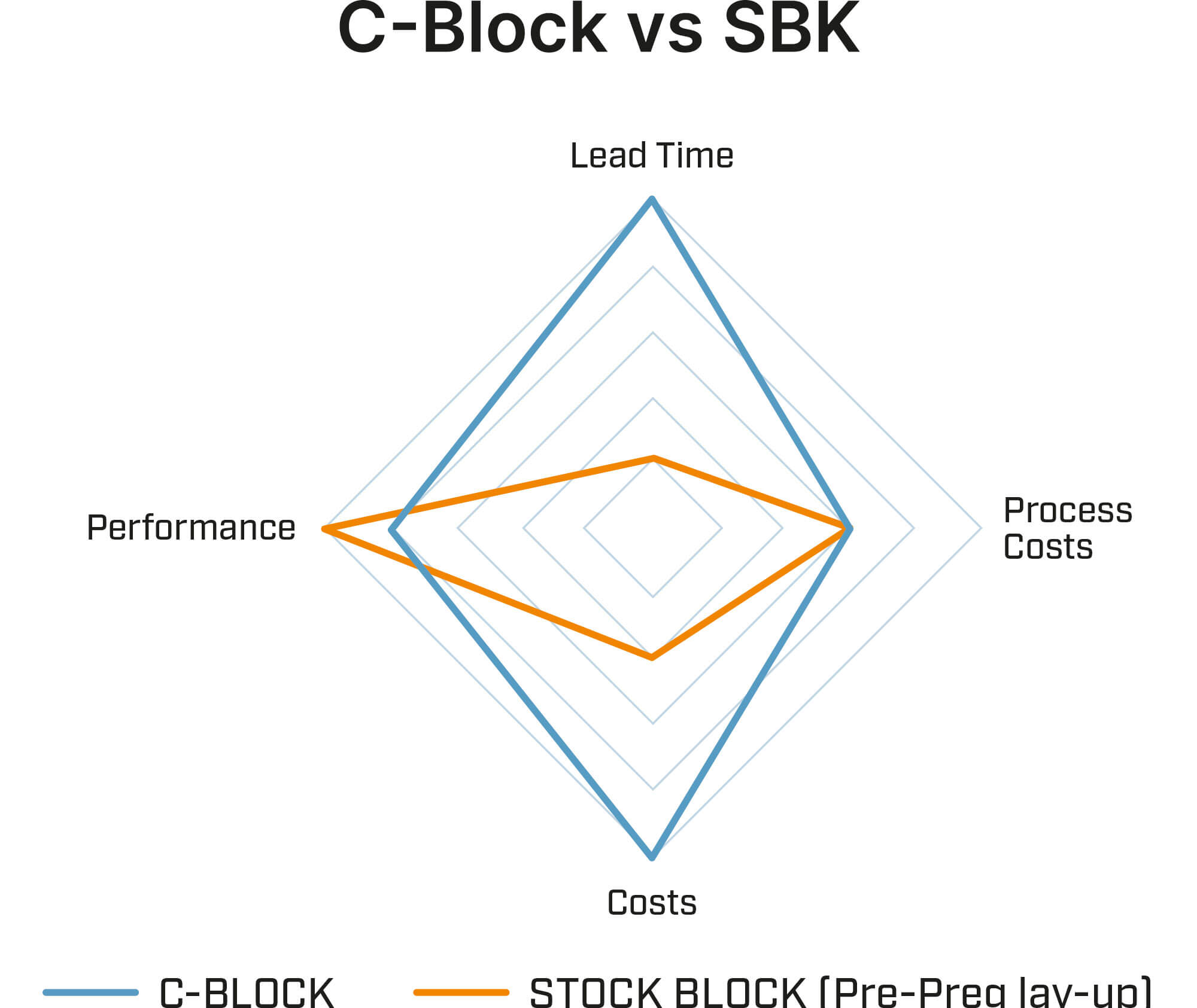

C-BLOCK 160 cost comparison vs. Stock-Block

Comparing some typical approaches for stock-block construction, the tendency is to use very balanced fabrics such as plain weave with weights not exceeding 400g/m2. Working with an iso-thickness 50mm and taking into consideration a standard weight of 380g/m2 for construction of a stock block, one would have a resulting weave of about 140 layers to be laminated with the following sequence:

| Sequence | Orientation |

|---|---|

| PLV 1 | 0/90 |

| PLV 2 | +/- 45 |

| PLV 3 | +/- 45 |

| PLV 4 | 0/90 |

Considering market prices, the raw material component alone is significantly higher than the C-BLOCK solution, and given the complexity of constructing thick slabs, the labour cost is absolutely significant, whereas the C-BLOCK solution allows costs to be reduced with a ready-to-use solution.

| Plate 750x500mm | Material Cost | Lay-Up Timing |

|---|---|---|

| SBH laminate 140 layers | 1.600 € | 2 days |

| C-BLOCK 160 | -50%* | Ready to use |

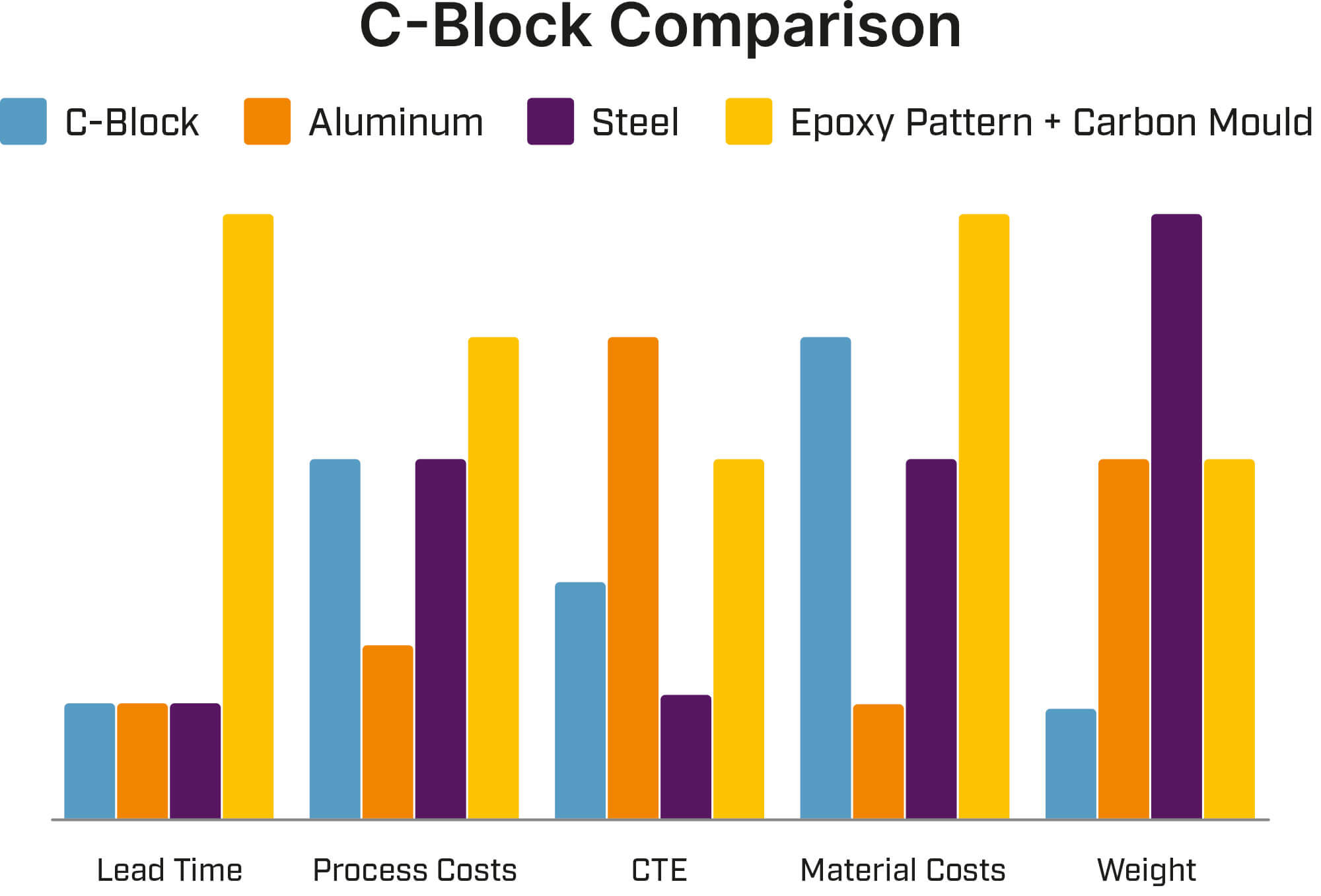

Mould accuracy and low CTE

Considering the intrinsic low thermal expansion coefficient of c-block, a mould was made intentionally without a scaling factor to allow effective evaluation of cte, as visible from the following table the values are confirmed to be low enough to place c-block as comparable to carbon-steel behaviour.

| Material | CTE μm/m°C |

|---|---|

| Carbon Steel | 12 |

| Aluminium | 24 |

| Aluminium Alloys | 23 |

| WB700N (Epoxy) | 40 |

| C-BLOCK 160 | α in-plane 13 ± 7 (μm/m)°C* |

*Available thicknesses: thickness 40 mm. Possibility of gluing board to reach higher thicknesses.

| Main Properties | Value |

|---|---|

| Density | 1,4 kg/dm³ |

| HDT (Heat Distorsion Temperature) | 160°C |

| CTE* | α in-plane 13 ± 7 (μm/m)°C* |

| Fiber Volume Fraction | 55% |

| Dimensions | 750X500X40mm |

*Calculated value relative to axis x (for further details contact the technicians).